If you’re new to the textile industry, it’s essential to understand the term RFD (ready for dyeing) fabrics. Many beginners or buyers may encounter this term without fully grasping its meaning. For professionals in fabric sourcing, dyeing, printing, or garment production, the dye-ready process is a crucial step for good color fastness.

What is RFD fabric?

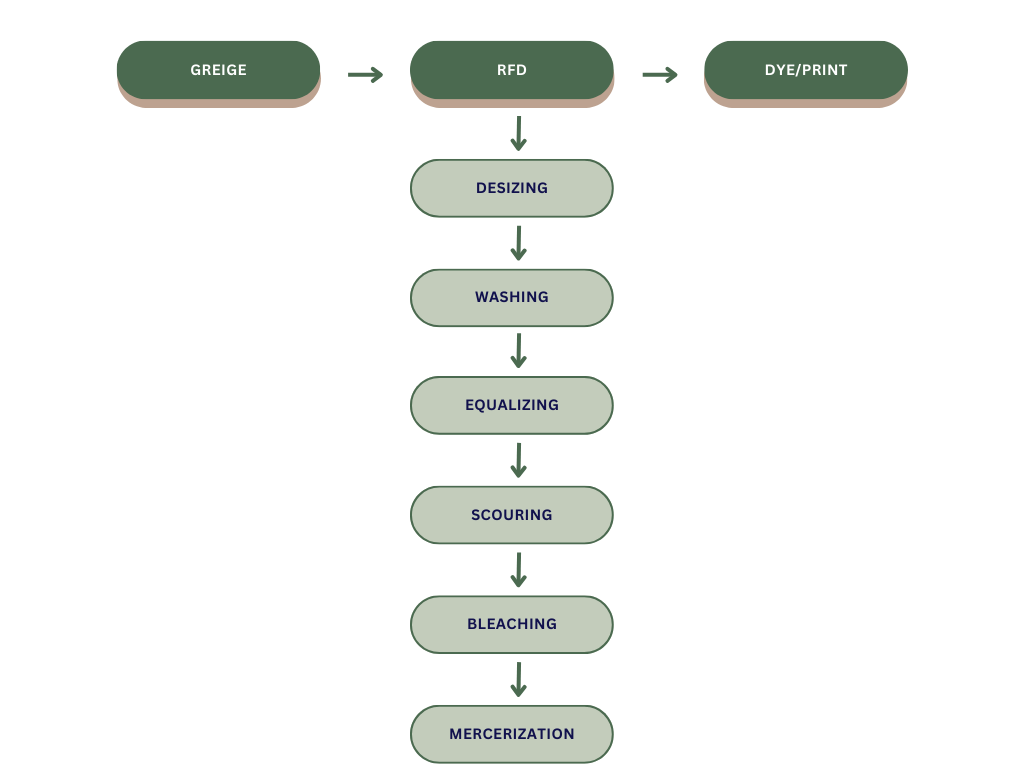

The RFD process is applied to fabrics or yarns. Fabrics are pretreated and processed to be ready for dyeing or printing. Before reaching this stage, the fabric is in its greige form, meaning it has not undergone any pretreatment.

To transform an ecru fabric into a ready-to-dye one and to remove impurities or residues that could affect the dyeing process, the fabric must undergo several processes, including desizing, washing, scouring, bleaching, and mercerization (each step is explained at the end of the article).

This preparation makes the fabric clean and highly absorbent for dyes.

Note for natural dyers: Ready-to-dye fabrics adhere perfectly to natural dyes. When working with plant-based dyes, it is important to understand that “ready-to-dye” does not mean that the fabric is pre-mordanted.

Why choose Green Tailor over other fabric suppliers?

In a world dominated by synthetic fabrics, finding truly natural fabrics that are also RFD can be a challenge. It has become such a habit to get any textile dyed that in the vast majority of the places where you will go to buy natural white fabrics, they will all be dyed synthetically in white or dyed in off-white/beige. Also, they have undergone the chemical steps called bleaching and mercerization.

At Green Tailor, we supply natural and RFD fabrics online made from organic cotton, linen, silk, and wool that are free from harsh or harmful chemicals. We are dedicated to producing and selling only RFD fabrics and products. Not a single article on our website had been dyed.

Along with fabric, we have sustainable products like scarves, garments, and accessories, which are safe for you and also better for the environment. All our organic cotton fabrics are GOTS-certified, and linen fabrics are OEKO-TEX-certified. We are dedicated to supplying high-quality natural fabrics and products to textile enthusiasts, designers, artisans, natural dyers, printers, and sustainable brands to achieve the best results.

For custom orders like yarn sourcing, fabric sourcing, or dyeing, feel free to contact us at [email protected].

Key steps for preparing RFD fabrics

Desizing removes sizing agents, such as starch or resins, used during the process of weaving. This step improves the fabric’s ability to absorb water and dye properly.

Washing cleans the surface of the fabric by removing loose dirt, dust, and water-soluble impurities.

Equalizing balances any irregularities that might have occurred during weaving or finishing. It includes properties such as moisture content, tension, or thickness.

Scouring is a deep cleaning process that removes natural waxes, oils, and other impurities embedded in the fibers. It leads to increased fabric absorbency and softness.

Bleaching is an optional step, meaning not all natural fibers require it. However, it removes the fabric’s natural color, odor, and other impurities from the greige fabrics.

Mercerization is also an optional step. It is a textile finishing process that enhances dye uptake and improves tear strength. Most commonly, this step is used in the production of cotton.

At Green Tailor, bleaching and mercerization are not carried out for our organic cotton and wool fabrics and products. In the case of some silk and wool fabrics, gentle bleaching is carried out only if required to achieve the desired purity and finish, always with care for the fabric and the environment.