In this blog, you’ll find a comprehensive guide to understand the most common types of fabrics, their characteristics and uses. Whether you are looking to start your own brand, or if you are a DIY enthusiast, or someone interested in textiles, this resource will help you understand the diverse world of fabrics.

It is essential to understand a few key points in order to communicate effectively with your suppliers and ensure you’re both on the same page.

Eight years back before we started Green Tailor, we had absolutely no knowledge and had to learn step by steps and from making mistakes. The aim with this article is to share with you the basics to understand how to communicate with your textile suppliers.

What are the different types of fabrics?

SEMI-SYNTHETIC FABRICS

Such as rayon, viscose ,modal, lyocell where the base materials are still plant-based which then go through some modern processing to create fabrics that are smoother and shinier.

SYNTHETIC FABRICS

Such as polyester,nylon,spandex which comes from petroleum-based that are processed and melted down, then spun into fibers that can be woven into fabrics.

hat are the differences between woven and knit fabric?

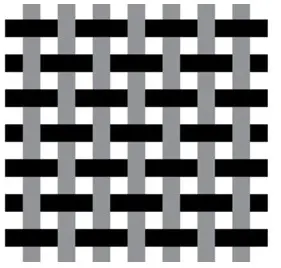

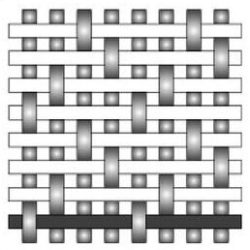

WOVEN FABRIC

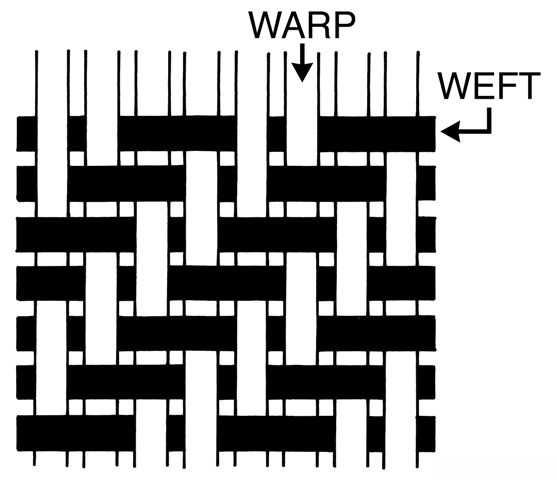

Construction : Made by interlacing two sets of yarns (warp and weft) at right angles using a loom.

Texture: Has a smoother,crisper feel, often more structured and tailored.

Wrinkle resistance: Tends to wrinkle more easily due to its stiffness.

Durability: Generally more durable and suitable for items that need strength, like jeans or upholstery.

Applications: Commonly used for garments like dress , scarves, shirts, trousers and jackets.

KNIT FABRIC

Construction: Created by interlooping a single yarn or multiple yarns, forming rows of loops.

Texture: Usually softer,with a more flexible, relaxed texture , often used in casual wear.

Wrinkle resistance : Less prone to wrinkling because of its stretch and elasticity.

Durability: Softer and more prone to snagging or pilling, though it’s often more comfortable to wear.

Applications: Often used for t-shirts, sweaters, leggings and other casual or stretchable clothing items.

Types of fabric construction techniques

Plain weave:

The simplest weave where the weft (horizontal) thread goes over and under the warp (vertical) thread in an alternating pattern. Found in fabrics such as muslin, cambric and voile.

Satin weave:

A weave with a smooth, glossy surface, where the weft yarn floats over multiple warp threads, often resulting in a lustrous fabric like satin

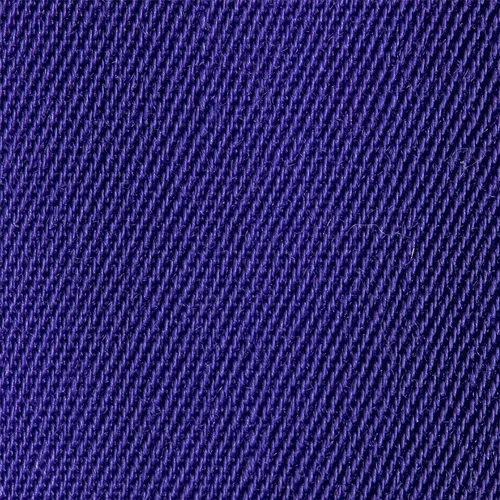

Twill weave:

A weave where the weft yarn passes over one or more warp threads and under two or more, creating a diagonal ribbing effect. Commonly used in denim and gabardine fabrics.

Jacquard weave:

It is a complex weave where each warp thread is individually controlled, allowing intricate patterns often with multiple colors and patterns. Used to create detailed, large-scale patterns such as florals, paisleys, or geometrics without the need for embroidery.

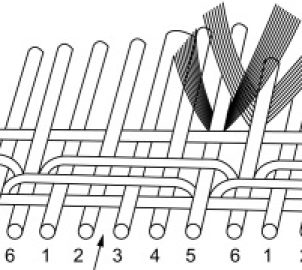

Pile weave:

A weave that creates a fabric with raised loops or cut loops, resulting in a plush texture. Used in fabrics like velvet, terry cloth, and corduroy.

Common vocabulary used for fabrics:

GSM (Grams per square meter)– A measure of fabric weight, indicating how many grams a square meter of the fabric weighs. Higher GSM means a thicker, denser fabric.

Width– The measurement across the fabric, from one selvedge to the other, typically in centimeters or inches. Standard widths can range from 44 inches to 60 inches or more, depending on the type of fabric.

Ready to dye – Fabrics that have been prepared for dyeing but have not yet been dyed. They are cleaned and treated, making them ideal for customization with dye.

Ecru – The natural, unbleached, and undyed color of fabric, from beige to a light beige for cotton and upto brown color for linens.

Dyed – Fabric that has undergone a process where color is added through dyes, creating uniform or patterned colors.

Block print – A traditional printing method where carved wooden blocks are dipped in dye or pigment and stamped onto fabric to create patterns.

Digital print – A modern printing method where designs are printed directly onto fabric using large-format digital printers, offering high precision and limitless color options.

Screen print – A printing technique where ink is pressed through a mesh screen onto fabric to create designs. This is typically used for bold, single-color or multi-color prints.

Counts – Refers to the number of threads (warp and weft) per inch of fabric. Higher thread count generally means finer, smoother fabric.

Yarn – The basic component of fabric, made from fibers twisted together. Yarn can vary in thickness, texture, and material (cotton, wool, silk, etc.).

Warp – The set of lengthwise threads that are held taut on a loom during weaving. The warp provides structure and stability to the fabric.

Weft – The horizontal threads that are woven over and under the warp threads. The weft is what creates the fabric’s pattern or design during weaving.

Shrinkage – The reduction in size of a fabric after washing or exposure to heat. Different fibers and weaves have varying degrees of shrinkage.

Tensile strength – A fabric’s ability to withstand tension or pulling without breaking. Fabrics with higher tensile strength are more durable.

This article is an overview of fabrics and its composition but it doesn’t end here, the world of textile is vast but we believe this article will help you to understand better the various vocabulary you will get to hear while communicating with your fabric suppliers. At Green Tailor, we offer a wide variety of ready to dye fabrics and products, perfect for you to create stunning designs out of it.

For any questions or enquiries, email us at [email protected]

Other links:

Cotton fabrics, Cambric,Poplin,Recycled cotton,Interlock,Double gauze squares, Double gauze wrinkles,Corduroy 6 wales, Corduroy 16 wales,Cotton slub,Voile,Linen fabrics,Wild silk,Smooth chiffon,Wrinkled chiffon,Velvet silk,Recycled silk,Satin 60, Satin 80, Nidhi fabric,Neha fabric,Adha fabric, Khadi organic,Kala cotton,Khadi 40,Khadi 55, Swatchbooks,Scarves,Garments,Accessories,Distributor,Services